Yaska EPX2800 6 Axis High Speed Painting Robot Arm With NX100-FM Controller

Product Details:

| Place of Origin: | Shanghai, China |

| Brand Name: | YASKAWA |

| Certification: | CE |

| Model Number: | EPX2800 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | YASKAWA EPX2800 industrial robot arm standard packing, WG:650 KG<br>NX100-FM Controller standard packing, WG: 120 KG |

| Supply Ability: | 10 Piece/Pieces per Month |

|

Detail Information |

|||

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising C |

|---|---|---|---|

| Local Service Location: | None | Showroom Location: | None |

| Condition: | New | After-sales Service Provided: | Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support, Online Support |

| Product Name: | EPX2800 Versatile High-Speed Painting Robot Arm | Number Of Axes: | 6 |

| Max Payload: | 20 Kg | Maximum Horizontal Reach: | 2779mm |

| Maximum Vertical Reach: | 4582mm | Pose Repeatability(ISO 9283): | ±0.5mm |

| Controller: | NX100-FM Controller | Mounting Position: | Floor |

| Warranty: | 1 Year | Port: | Shanghai |

| High Light: | Yaska Painting Robot Arm,High Speed robotic spray arm,High Speed Painting Robot Arm |

||

Product Description

EPX2800 Versatile 6-Axis High-Speed Precision Painting Robot Arm/dispensing Robot Arm with NX100-FM controller for Yaskawa Motoman

Main Specifications:

Model: EPX2800

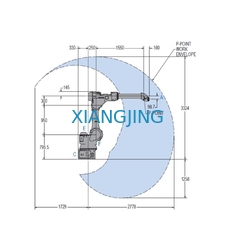

Maximum Horizontal reach:2779mm

Maximum Vertical reach:4582mm

Maximum payload:20kg

Pose repeatability:± 0.5mm

Number of axes:6

Weight:650 kg

![]()

EPX2800 Introduction:

1. Motoman Robotics is a global leader with a large paint robot install base

2. High wrist/upper arm payload capacity for mounting paint application equipment

3. Easy-to-use touch screen teach pendant

4. MotoSim

1. High-speed, versatile six-axis EPX2800 robot is ideal for automotive and other

industrial coating applications.

2. Offers superior performance and creates smooth, consistent finish with outstanding

efficiency for painting and dispensing applications.

3. Hollow wrist design is ideal for painting contoured parts such as interior/exterior

surfaces; well-suited for mounting spray equipment applicators. Inside diameter

is 70 mm (2.75"). Interference between the hose and parts/fixtures is avoided;

ensures optimum cycle time and robot reach/access.

4. Factory Mutual (FM) approved for Class 1, Div. 1 use in hazardous environments.

5. 20 kg (44.1 lb) payload; 2,779 mm (109.4") horizontal reach; 4,582 mm

(180.4") vertical reach; ±0.5 mm (±0.02") repeatability.

6. Highly flexible, compact design.

1. Includes application-specific software for paint applications.

2. Coordinates operation of robot and painting devices, including spray gun.

3. Supports gun control instructions such as spray start/stop and painting conditions.

4. All painting position parameters can be filed and saved.

5. Supports standard networks (such as DeviceNet, ControlNet, Profibus-DP and

Interbus-S), enabling connection to paint equipment controllers and production line

controllers.

Applications:

painting and dispensing

| EPX2800 Specification | ||

| Structure | Vertical Joint-arm type | |

| Controlled Axis | 6 | |

| Payloard | 20kg | |

| Vertical Reach Range | 4,582mm | |

| Horizontal Reach Range | 2,779mm | |

| Repeatability | ±0.5mm | |

| maximum Motion Range |

S-Axis(Turning/Sweep) L-Axis(Lower Arm) U-Axis(Upper Arm) (relative angle of lower arm) R-Axis(Wrist Roll) B-Axis(Bend/Pitch/Yaw) T-Axis(Wrist/Twist) |

±150º +120º/-45º +90º/-85º

±360º ±360º ±360º |

| Maximum Speed | 2.0 m/s | |

| Approximate Mass | 650 kg | |

| Brakes | All axis | |

| Powser Comsumption | 5 KVA | |

| Allowable Moment |

R-Axis B-Axis T-Axis |

77.4N·M 49.9N·M 19.6N·M |

| Allowable Moment of Intertia |

R-Axis B-Axis T-Axis |

2.45kg·m2 1.20kg·m2 0.20kg·m2 |

| Mounting | Floor | |

| NX100-FM Controller Specification | ||

| Structure | Free-Standing, Enclosed Type | |

| Dimension | 500(w)X1400(h)X550d | |

| Approximate Mass | 120kg | |

| Cooling System | Indirecting Cooling | |

| Ambient Temperature |

During Operation:0ºC-40ºC During Transit and Storage:0ºC-40ºC |

|

| Relative Humidity | 90% max. non-condensing | |

| Primary Power requirements | Optional extermal transformer allows 240/480/575 VAC at 50/60 Hz | |

| Grounding |

Grounding resistance: ≤100 ohms Separate ground required |

|

| Digital I/O | Specialized signals: 28 inputs and 7 outputs General signals: 40 inputs and 40 outputs (Specialized allocation: 24 inputsDgital/0 and 4 outputs; General allocation: 16 inputs and 16 outputs) Max. I/O (optional): 4,096 inputs and 4,096 outputs |

|

| Position Feedback | By absolute encoder | |

| Drive Units | Servo packs for AC servo motors | |

| Accel/Decel | Software servo control | |

| Program Capacity |

JOB: 600,000 steps; 10,000 instructions Concurrent I/O ladder: 10,0000 steps |

|

| Fieldbus Options |

CC Link, DeviceNet, Ethernet, EtherNetlP, EtherCAT, PROFINET |

|

| Ethernet | 10 Base T/100 Base TX | |

| E-Stop | Controlled stop | |

| Safety | Dual-channel Emergency Stop Pushbuttons,3-position Enable Switch, Meets ANSI/RIAR15.06-1999 and Canadian safety standards | |

| Pendant Dim. (mm) | 169 (w)x314.5 (h)x 50 (d) | |

| Pendant Mass | 0.99 kg | |

| Pendant Playback Buttons | Teach, Play, Remote, Servo On, Start, Hold, Emergency Stop, Edit Lock (Play Mode enabled on controller) | |

![]()

![]()

![]()

1.Swift delivery

For common parts, we can deliver the goods within 3 days

2.Original products

All the products we sell are from origin manufacturer. We will submit all the manufacturer documentation while we finish delivery.

3.Quality Assurance

4.Technical Support

Including inspection,repair and maintenance, we can give all kinds of technical support.

5.Quickly responce

Our staffs will keep 24h online and answer your question very quickly.