SP80 Used Robot Arm With Robot Teach Pedant RD500 Welder

Product Details:

| Place of Origin: | China |

| Brand Name: | YASKAWA |

| Certification: | CE |

| Model Number: | SP80 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | Regular packing ,100% Factory Sealed. |

| Supply Ability: | 10 Set/Sets per Month |

|

Detail Information |

|||

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts | Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Printing Shops, Construction Works , Energy & Mining, Advertising Company |

|---|---|---|---|

| Local Service Location: | None | Showroom Location: | None |

| Warranty: | 1.5 Years | Condition: | New |

| After-sales Service Provided: | Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support, Online Support | Product Name: | SP80 Spot Welding Robot |

| Number Of Axes: | 6 | Max Payload: | 80 Kg |

| Maximum Horizontal Reach: | 2236 Mm | Maximum Vertical Reach: | 3751 Mm |

| Repeatability(ISO 9283): | ±0.07mm | Teach Pendant: | YRC1000 Controller |

| Mounting Position: | Floor, Wall, Tilt Or Ceiling | Weight: | 655 Kg |

| Port: | Shanghai | ||

| High Light: | SP80 Used Robot Arm,YASKAWA spot welding robot,spot welding robot RD500 Welder |

||

Product Description

Yaskawa Motoman SP80 spot welding robot flexible and fast with YRC1000 robot controller and robot teach pedant RD500 welder

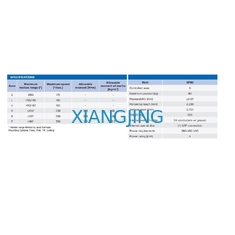

Main Specifications:

Maximum horizontal reach: 2236mm

Maximum vertical reach:3751mm

Maximum payload:80 kg

Number of axes:6

Engineered for superior spot welding performance, the six-axis SP80 robot offers exceptionally quick axis speeds and acceleration capabilities to reduce air-cut time. While a wide wrist motion range eliminates interference, a slim profile design facilitates reaching into tight spaces and close proximity placement of robots for high-density workcells. An integrated spot harness improves robot wrist motion, and servo gun and DC timer technology facilitate quality production output. Spot monitoring, waveform graphing, controller connectivity, and a single power and control cable make the SP80 the ideal robot to simplify the welding process for complicated parts.

Key Benefits

1. Single robot-to-controller cable connectionenables fast setup

2. High-speed robot motion reduces air-cuttime for spot gun

3. Flexible wrist motion range simplies programming of complicated parts.

4. Reduced profile design enableshigh-density installation.

Specifications

1. 80 kg payload with spot harness

2. 88 kg payload without spot harness

3. 2,236 mm horizontal reach

4. 3,751 mm vertical reacht

5. 0.07 mm repeatability

6. Floor mounted

Features

. Flexible six-axis robot features exceptionally fast axis speeds andacceleration to reduce air-cut timeand increase production output.

. Wide wrist motion range eliminates interference and improves application fexibility.

. Slim profile design allows reachinginto confined spaces and close proximity placement of robots forhigh-density workcells.

· Integrated spot harness improveswrist flexibility and reduces downtime.

. Servo gun and DC timer technology optimized for productivity and quality.

· Spot monitoring and waveform graphing helps check and troubleshoot welding conditions.

· Controller connectivity provides simple wiring to spot timers

. Robot pendant application for programming Medar and Nadex brand timers.

. Single power and control cable reduces wiring time and increases work efficiency.

. New robot harness design for improved diagnostics and maintenance.

. Spot harness connections

- Connections from base to upper arm

· DeviceNet signal and power

- Connections from base to wrist (gun)

· Servo motor and encoder

· Airhose(2)6.5mmID,(1)8mmID

· Water hose (4) 8 mm ID

. Weld power (2) 22 mm2, (1) 14 mm2

. Transformer thermostat (3) 0.75 mm2

. User I/O (9) twisted pair + (1) 0.3 mm2

. Home position data can be saved without battery connection for easy maintenance.

· The SP80 has an lP67-rated wrist and an IP54 body standard.

. The SP80 can be floor-, wall-, tilt-or ceiling-mounted. Brakes areincluded on all axes.

. Compact YRC controller utilizes the lightweight standard teach pendant with intuitive programming.

| Product Name | SP80 6-axis welding robot |

| Model | SP80 |

| Application | Spot Welding |

| Maximum reach | 2236 mm |

| Maximum payload | 80 kg |

| Pose repeatability (ISO 9283) | ± 0.07 mm |

| Number of axes | 6 |

| Mounting position | Floor mounted |

| Footprint | 2236mm x 3751mm |

| Weight | 655 kg |

| Protection rating | IP54 |

| Controller | YRC1000 |

![]()

1.Swift delivery

For common parts, we can deliver the goods within 3 days

2.Original products

All the products we sell are from origin manufacturer. We will submit all the manufacturer documentation while we finish delivery.

3.Quality Assurance

4.Technical Support

Including inspection,repair and maintenance, we can give all kinds of technical support.

5.Quickly responce

Our staffs will keep 24h online and answer your question very quickly.