5 Axis Used Yaskawa Robot

Product Details:

| Place of Origin: | Shanghai, China |

| Brand Name: | Yaskawa |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 5 axis robot arm YASKAWA MPL80 II pick and place machine 80kg Payload 2061mm Arm industrial robot<br>ONE YASKAWA MPL80 II industrial robot 5 Axis robot arm for pick and place machine packing with fumigation wooden frame, WG:605KG<br>Controller and other pa |

| Supply Ability: | 5 Piece/Pieces per Month |

|

Detail Information |

|||

| Product Name: | 5 Axis Robot Arm MPL80 II Pick And Place Machine Industrial Robot | Function: | Multifunctional |

|---|---|---|---|

| Controlled Axes: | 5 | Max. Payload: | 80kg |

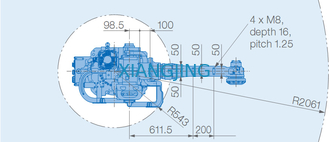

| Repeatability: | ±0.07mm | Max. Working Range R: | 2061mm |

| Temperature: | 0-45 ℃ | Humidity: | 20%-80% |

| Weight: | 550kg | Power Supply, Average: | 4.0KVA |

| Condition: | New | Video Outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Ordinary Product |

| Warranty Of Core Components: | 1 Year | Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Gear |

| Warranty: | 1 Year | After-sales Service Provided: | Free Spare Parts, Field Maintenance And Repair Service, Video Technical Support, Online Support |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Local Service Location: | United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, India, Russia, Thailand, Japan, South Korea |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction Works , Energy & Mining, Advertising Company | Showroom Location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Indonesia, India, Mexico, Russia, Spain, South Korea, Bangladesh, Nigeria, Japan, Malaysia, Australia |

| Port: | Shanghai | ||

| Highlight: | 5 axis Used Yaskawa Robot,2061mm 5 axis robot arm,80kg Payload Used Yaskawa Robot |

||

Product Description

5 axis robot arm YASKAWA MPL80 II pick and place machine 80kg Payload 2061mm Arm industrial robot

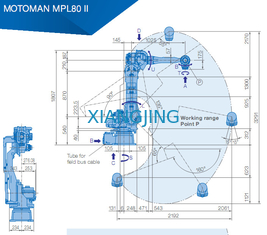

The MOTOMAN MPL80II is a 5-axis Palletizing Robot with a payload of 80 kg and a reach of 2,061 mm. This model is derived from a 6-axis-Handling robot and tuned for High Speed and Accelerations.

Based on the reliable Sigma5 Servo Technology, this robot is easy to install and deploy.

| Axes 5 |

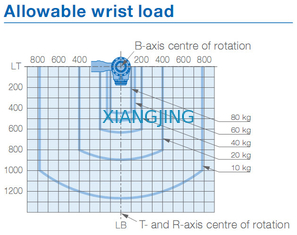

| Payload: 80 KG (176.37 lbs) |

| Reach: 2061 MM (81.14 in) |

| Repeatability: ±0.07mm (.002 in) |

| Robot Mass: 550 KG (1,212 lbs) |

| Structure: Articulated |

| Robot Motion Speed |

| S-Axis 170 °/s (2.96 rad/s) |

| L-Axis 170 °/s (2.96 rad/s) |

| U-Axis 170 °/s (2.96 rad/s) |

| B-Axis 170 °/s (2.96 rad/s) |

| T-Axis 350 °/s (6.10 rad/s) |

| Robot Motion Range |

| S-Axis - ±180° |

| L-Axis - 135°-90° |

| U-Axis - 35°-160° |

| B-Axis - ±15° |

| T-Axis - ±360° |

Key benefits:

- Extremely high acceleration and axis speed values;

- Compact design allows maximum performance using minimal floor space;

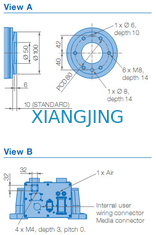

- Increased durability of hose package by internal cable wiring;

- Optional: Palletizing robot software package.

![]()

| Product Name | 5 axis robot arm YASKAWA MPL80 II pick and place machine 80kg Payload 2061mm Arm industrial robot |

| Model | MPL80 II |

| Application | Handling & General Application |

| Maximum reach | 2061mm |

| Maximum payload | 80kg |

| Pose repeatability (ISO 9283) | ± 0.07mm |

| Number of axes | 5 |

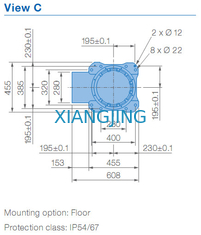

| Mounting position | Floor |

| Weight | 550kg |

| Protection rating | IP67 |

| Controller | DX200 |

| Motion range | |

| S | 180° to -180° |

| L | 135° to -90° |

| U | 35° tp -160° |

| R | |

| B | 15° to -15° |

| T | 360° to -360° |

![]()

MPL80 II Introduction:

![]()

The versatile and powerful 5-axis MOTOMAN MPL80 II robot provides high performance in case palletising, bag palletising, order picking and many further logistical tasks for end-of-line or distribution center automation.

![]()

Its extensive vertical reach of 3291 mm combined with 2061 mm horizontal reach enables high palletising loads. Empty tubes for internally routed airlines and cables from base to end-of-arm tool maximize system reliability.

![]()

The MPL80 II is driven by the high-perfomance DX200 controller which is available with the optional Category 3 Functional Safety Unit (FSU), providing a variety of new safety functions.

KEY BENEFITS

• Flexible and powerful

• High Payload: 80 kg

• Maximum reliability, empty tubes for internally routed airlines and cables

• Internally routed fieldbus connection (optional) to T-axis/tool

• Enhanced Safety Functions for DX200 Functional Safety Controller (FSU)

Applications:

Handling & General Application

![]()

1. Swift delivery

For common parts, we can deliver the goods within 3 days

All the products we sell are from origin manufacturer. We will submit all the manufacturer documentation while we finish delivery.

Including inspection,repair and maintenance, we can give all kinds of technical support.

Our staffs will keep 24h online and answer your question very quickly.